We saw the first hurricane of the season (Hurricane Arthur) hit the east coast over the Fourth of July holiday weekend. While Arthur was downgraded to a category one storm resulting in limited damage, the upcoming hurricane season brings to mind new building techniques that are adapted to limit property and building damage caused by hurricanes, tornados and other storms

One product and technique increasingly employed is the insulated concrete form or ICF. ICF style walls have been in the marketplace since the 1940’s, however recent improvements are leading to their increased usage especially in hurricane-prone and tornado-prone areas of the country. The ICF industry has become standardized in recent years.

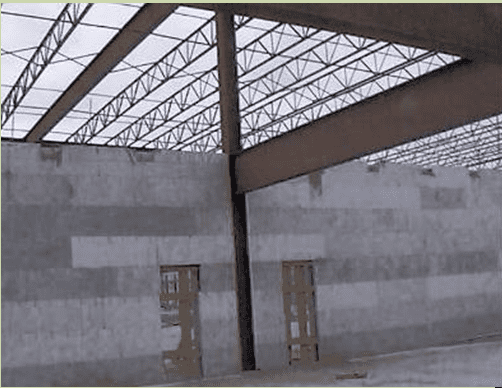

The basic ICF method is a modular system of rigid thermal insulation that stays in place for pouring reinforced concrete to form the structure for walls, floors and roofs. The system locks together like a Lego’s project and brick or EFIS can be added as an exterior finish and drywall added for an interior finish. The reinforced concrete does the work while the insulation provides the energy savings and quieting effect.

The benefits are multiple. The panels resist mildew and moisture, they provide energy efficiency by reducing the cost to heat and cool (up to 50% savings over conventional wood frame buildings), the insulation values comply with LEED green building criteria and the forms are lightweight and easy to assemble resulting in a quick installation. The monolithic concrete of ICF walls with vertical and horizontal steel reinforcement provides the structural strength needed to resist storm damage. ICF walls are designed to withstand winds up to 300 mph. The systems typically have a four-hour fire rating and are 87% quieter than standard wood frame buildings.

The cost of using ICF can add from 3 to 5% onto the project’s cost, however, if you have basements or large open spaces to consider then the overall cost of ICF construction can actually reduce a project’s cost from 20–30% due combining several traditional process steps into just two basic ones: assembling the modular frame and then pouring the concrete. Plus, there is an energy savings to consider in the overall project savings as ICF projects are less expensive over time to heat and cool the same amount of space.

If you would like to know more about ICF systems and if they might be right for your project, give us a call at Smet Construction Services. We’d love to sit down with your to discuss your ICF construction needs.

For more information:

Greg Polacheck. Director of Market Research

[email protected]